Lagging to Leading to Transformational Indicators: Measuring the Contribution of Value

At some point, how we do safety better is answered by removing effort that is no longer value-added, even though at one point in time, it might have been.

Measuring activities to determine the health of improvement efforts or culture tells you very little if excellence is your goal. Excellence is not just zero injuries or incidents; it is the ability to win through the achievement of great results, with strong and confident insight into how the results were achieved, and a culture that focuses on a continuous improvement mindset.

Many well-intended organizations suffer from a programmatic focus and demonstrate an activities-based culture, whether these activities add value or not. For years, the safety profession, in particular, has tried to compete with the business goals of production by integrating activities and thinking into everything to overcome this competition. If there is no real or perceived value that is yielded by the activities, the competition continues, as it was not correctly addressed. Our strategy shouldn't be to compete; it should show how we will win by adding value. Zero injuries or incidents is the byproduct of the value of excellence, not the final goal.

Effective safety strategy, however, is still surprisingly lacking in many organizations. I have named the "strategy" in place for most the Perpetual Cycle of Avoiding FailuresSM, with zero injuries being the primary, misguided goal. The cycle repeats like this: 1) Review current injury rate. 2) Set new injury rate or objective. 3) Develop a list of initiatives (or programs). 4) Execute on the efforts. 1) Review current injury rate.

Problems arise when the rates improve. Most leaders know correlation doesn't mean causation, but this is forgotten with improved results: "We had better performance and we were doing these things; therefore, we had better performance because we were doing these things." Sounds logical, doesn't it? This is just as flawed logic as individuals who define safe as zero injuries: "Safe means not getting hurt, so therefore, anything I do that doesn't get me hurt must be safe!"

Alternatively, it is easy to become distracted when rates don't improve or with each new incident when the search is revived for what else can be done. More seems to be the answer or driver for improvement, rather than how we do safety better. At some point, how we do safety better is answered by removing effort that is no longer value-added, even though at one point in time, it might have been.

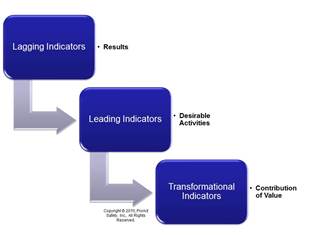

An effective strategy is a framework of choices an organization makes to determine how to capture and deliver value. This strategy answers, "How will we win and know we are winning?" These choices have been made by many ProAct Safety clients over the years with a culmination of advancements in what is measured (see Evolution of Safety Excellence MeasurementsSM). These organizations evolved from measuring lagging indicators (their results) to leading indicators (typically inputs and activities) to transformational indicators (measurement of contributed value from the activities to the results).

An effective strategy is a framework of choices an organization makes to determine how to capture and deliver value. This strategy answers, "How will we win and know we are winning?" These choices have been made by many ProAct Safety clients over the years with a culmination of advancements in what is measured (see Evolution of Safety Excellence MeasurementsSM). These organizations evolved from measuring lagging indicators (their results) to leading indicators (typically inputs and activities) to transformational indicators (measurement of contributed value from the activities to the results).

Consider your health as an analogy: A lagging indicator might be having or not having a heart attack. Exercise, calories burned versus consumed, and diet would be leading indicators and are comparable to how we measure our leading indicators in safety: activities and effort. However, if you check your blood pressure and it is high or has increased and you are making healthy eating decisions and regularly exercising, the answer is rarely more diets and increasing exercise. You might need a different intervention, as more is rarely the answer. Your blood pressure is a transformational indicator that tells you the value derived from your activities.

In both health and safety, we must all evolve to measure not just the things we do to try to improve the lagging indicator results, but also the contribution of value from our activities to our results. For safety, the following are proven examples of transformational indicators: Desired Beliefs, Emotions, Knowledge Levels, Competencies, Behaviors, and Organizational Story-Telling.

Consider training: If we measure only attendance but not whether, as a result, people know what we need them to know, believe what we need them to believe, and do or are able to do what we need them to do, is there any real return on investment of time and resources? If we had people in a class and results improved, should we trust how real and sustainable the results are?

Organizations on the path toward excellence in safety performance and culture realize they need a strategy. Strategy is making trade-off choices (what will we do, not do, or stop doing) to win. As part of their strategy, the focus and measurements evolve from results and activities toward capturing and delivering value to the customers of their safety efforts. In your organization, what transformational indicators would tell you the value contributed by your safety efforts? Focus on this and you will significantly increase your chances of winning.

This article originally appeared in the March 2015 issue of Occupational Health & Safety.